Equipment List

Post Press

Stitching, Inserting, Labeling

- 3 Muller Martini stitchers with inkjet addressing

- 1 Muller Martini 227 inserters with inkjet (6 into 1)

- 1 Muller Martini SLS 2000 inserter (8 into 1)

- 2 Kansa inserters with inkjet (4 into 1)

- 1 Muller Alpha Liner inserter (14 into 1)

Addressing

- 3 Inkjet labeling lines

- 9 Inkjet systems

Cutting, Sealing, Wrapping

- 2 Guillotine cutters

- 1 Kirk Rudy wafer sealer

- 1 Shrink wrap

Buhrs 3000 Polybag System

- Cheshire label for mail copies

- Onsert up to 3 pieces plus product*

Kolbus Tipping Machine/Sticky Note

- Multiple position

- Sticky note applicator

Pressroom (Coldweb)

DGM-1, 16 Units Coldweb

- 22-3/4” cutoff

- Installed as four 4-color towers

- Newsprint and uncoated paper

- Tabloid, magazine and broadsheet formats

DGM-2, 16 Units Coldweb

- 22-3/4” cutoff

- Installed as four 4-color towers

- Newsprint and uncoated paper

- Tabloid, magazine and broadsheet formats

- On-press stitching

- Upper former

DGM-1 and DGM-2 combine to run as a

32 unit, 8-tower press

DGM-3, 24 Units Coldweb

- 22-3/4” cutoff

- Installed as six 4-color towers

- Newsprint and uncoated paper

- Tabloid, magazine and broadsheet formats

- Upper former

Goss HV-A, 14 Units Coldweb

- 22-3/4” cutoff

- Newsprint and uncoated paper

- Tabloid, magazine and broadsheet formats

Goss HV-C, 16 Units Coldweb

- 22-3/4 cutoff

- Newsprint and uncoated paper

- Tabloid, magazine or broadsheet formats.

Pressroom (Heatset)

Komori, 4 Units Heatset

- 22-3/4” cutoff

- Gloss coated, matte coated and uncoated paper

- Magazine and tabloid size products, covers and inserts

- Delta-fold and digest products

- Double-parallel folder

- Dryer and chills

- Conti-web splicer

Rotoman, 8 Units Heatset

- 22-3/4” cutoff

- Gloss coated, matte coated and uncoated paper

- Magazine and tabloid size products, covers and inserts

- Sheeter for flat-sheet products

- Two-pass dryer and chills

- Plow folder

- Two butler splicers

Prepress

Prinergy PDF Workflow

Prinergy is a single page based PDF workflow speeds proofing and correction cycle time. It integrates inline PDF Trapping and color management and allows for custom built dot gain curves at time of output.

ZERO Down Time

Our workflow includes a back-up server that can be activated in the event that the “primary” server goes down.

Kodak Platesetter

Redundancy in the plate room using multiple high-speed devices. Thermal technology images a much sharper dot for better reproduction on press. Reliable output from 1200 to 2400 dpi using chemical-free plate processing.

InSite Online Proofing

InSite is a browser based, secure online soft proofing.

Fast, downloads to your screen speeds up the process.

InSite offers the ability to approve or reject proofs and sign off with your “digital signature”. Hi-Resolution Pan & Zoom, ability to measure ink densities and annotate changes. Allows multiple users to collaborate simultaneously.

Kodak Inkjet Matchprint Proofing

Industry standard Matchprint color technology with custom icc profiles allows these (4) proofers to simulate the final printed product.

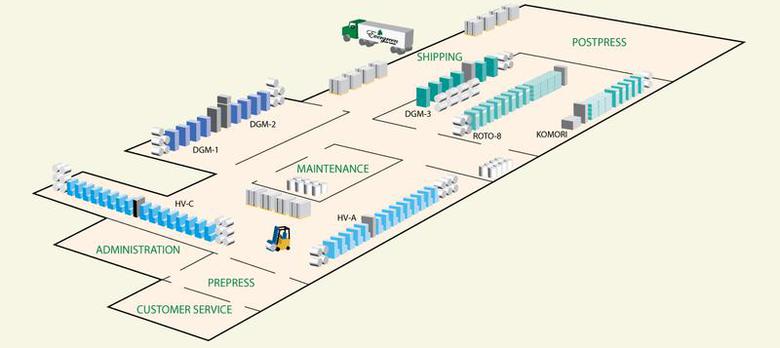

Ideal Location...101 Haag Avenue, Bellmawr, NJ

Evergreen Printing Company is located in Southern New Jersey, twenty minutes from Philadelphia and two hours from metro New York and Washington, DC. We are less than a mile from exit 3 of the

New Jersey Turnpike. Scroll down to see our coldweb,

heatset, prepress and postpress equipment list.

Tremendous

Capacity for Color

and High Page Counts

Evergreen operates three, DGM440

presses, two with 16 units and one with

24 units, plus two Goss HV presses with

14 units and 16 units.This gives us tremendous

capacity to provide a wide range of page counts and color.

Evergreen also operates two heatset presses for gloss covers, magazines and tabloid size publications.

| ||||||

Evergreen Printing Company 101 Haag Avenue, Bellmawr, NJ 08031 800-922-0252 www.egpp.com

Evergreen

Printing Company

101 Haag Avenue

Bellmawr, NJ 08031

856-933-0222

www.egpp.com